The choice between dock levelers and dock plates plays a big role in warehouse and loading facility operations. Dock levelers can handle weights from 25,000 to 35,000 pounds. Dock plates support loads between 7,000 to 15,000 pounds. The equipment’s weight capacity stands out as a major difference that shapes your operational decisions.

The cost structure varies between these options. A mechanical edge-of-dock leveler starts at $2,500, while hydraulic dock levelers range from $7,000 to $10,000. Hydraulic dock levelers prove more economical over time and need minimal upkeep. The installation timeline differs too. Teams can mount exterior dock levelers within 1-2 days per dock. Pit-style dock levelers need 4-6 weeks of facility downtime.

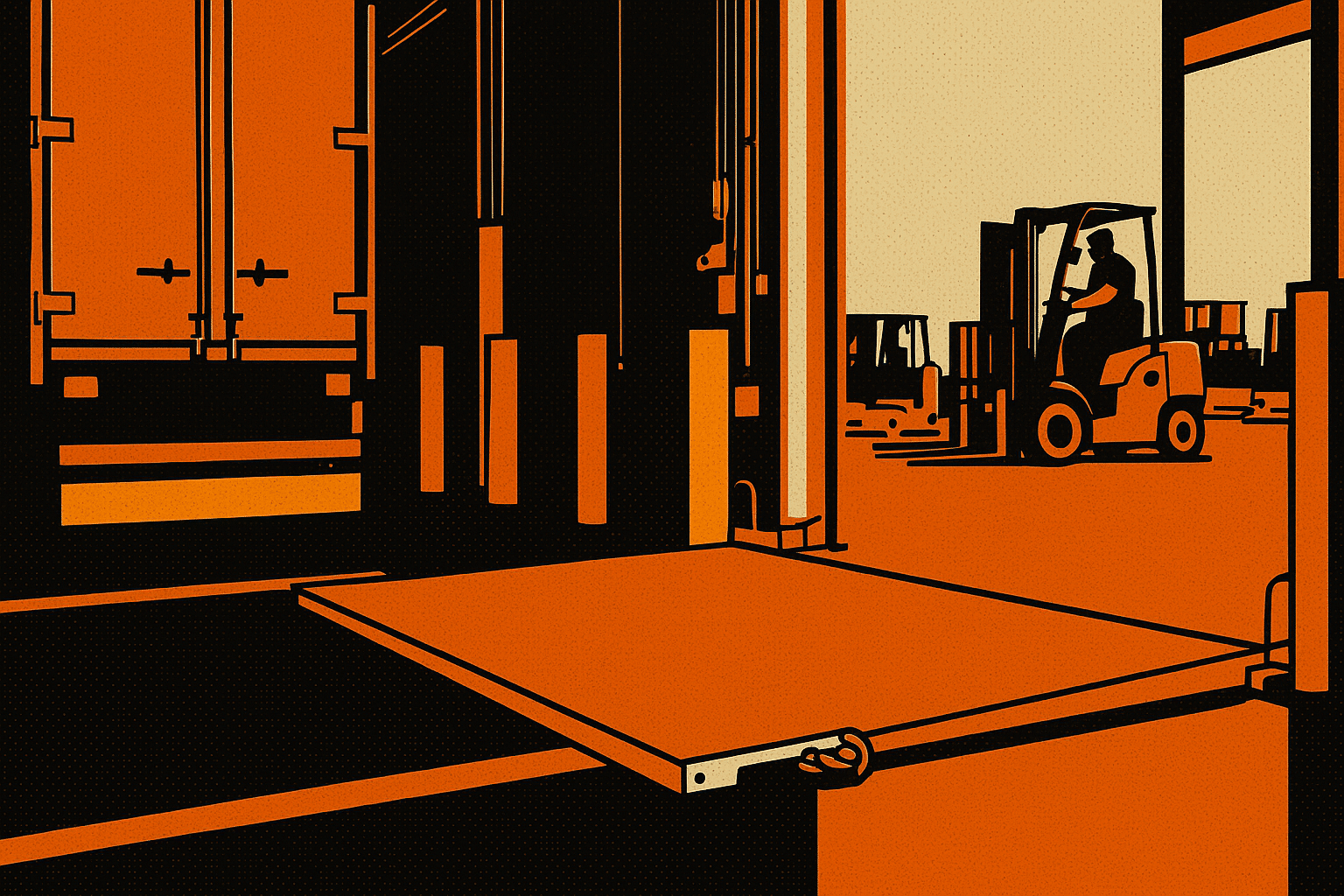

Let’s get into the main differences between these loading dock options and explore mechanical and hydraulic varieties. You’ll learn which equipment matches your facility’s needs. The discussion will give you the tools to pick between a dock leveler and dock plate based on your operations, budget and future plans. Remember, before you decide to install anything it is important to consult with a professional.

What is the difference between a dock leveler and a dock plate?

You need to know the basic differences between dock levelers and dock plates to make smart choices about your loading dock equipment. Your choice will affect how well your operations run, how safe they are, and how much work gets done.

Definition of dock levelers

Dock levelers work as permanent bridges at loading docks. They create smooth paths between warehouses and truck trailers. These reliable platforms attach to the dock face or sit in a pit under the dock floor. Each dock leveler has an adjustable metal plate (called a lip) that reaches onto the truck bed. This creates a continuous path for material handling equipment. Most dock levelers use galvanized steel or hot galvanized steel. This makes them very strong and perfect for heavy-duty work. The height adjusts to match different vehicles, so trucks can load and unload no matter how high their beds are.

Definition of dock plates

Dock plates offer a different solution as portable metal bridges that connect loading docks to trucks. These flat metal pieces usually come in lightweight aluminum, though steel versions work better for heavier loads. Dock plates shine when the dock and truck heights are close, usually less than 5 inches apart. Workers can move them easily between different loading spots. Yellow painted borders mark the edges for safety, but they don’t have all the safety features you’ll find in dock levelers.

Key functional differences

Installation method and load capacity set these two types of equipment apart. Dock levelers stay fixed in place and can handle much more weight, hydraulic models support up to 100,000 pounds. Dock plates work better for lighter loads moved by hand trucks, pallet jacks, or people walking across.

Dock levelers also come with different ways to operate them. Some use hydraulic systems with electric pumps, others use spring mechanisms, and some work with inflatable airbags. Dock plates keep things simple with their basic design.

Size makes another big difference. Dock levelers can stretch up to 12 feet long and more than 6 feet wide. This dwarfs the typical dock plate that measures just 3-5 feet across. The size gap means dock levelers safely handle forklifts and heavy machinery, while dock plates work better with manual equipment.

Types of dock levelers and dock plates

Loading dock equipment comes in many options today. Each facility has its own needs based on how they operate.

Hydraulic dock levelers

Hydraulic dock levelers work with an electro-hydraulic system. Operators can raise or lower the platform by simply pushing a button. These units work better than mechanical ones because no one has to pull or lift anything. They can handle very heavy loads up to 100,000 pounds, which makes them perfect for busy loading docks. The simple design uses just three main parts: the power pack, deck cylinder, and lip cylinder. This means less maintenance and better durability in tough environments.

Mechanical dock levelers

Mechanical dock levelers work with a spring-biased lifting mechanism and a hold-down device. The operator pulls a release chain to start the process. This lets the lifting mechanism raise the deck and extend the lip. Next, they walk down the deck until the extended lip sits on the vehicle bed. These units cost less upfront than hydraulic ones but need more regular maintenance. All the same, they work great for places that handle lighter loads or don’t use them as often.

Edge-of-dock levelers

Edge-of-dock levelers (EODs) attach right to the dock face instead of going in a recessed pit. These space-savers help bridge the gap between dock and truck when height differences are small. EODs can work with trucks about 5 inches above or below dock height and can handle up to 35,000 pounds. The best part? You don’t need a pit installation. This means faster setup, better security against theft, and fewer pest problems.

Portable dock plates

Portable dock plates are light aluminum structures you can quickly set up and remove. We used these mainly for hand trucks, pallet jacks, and people walking across. They have locking legs underneath to stay in place during use. You can easily move them between different loading areas. Remember that most dock plates won’t work with powered equipment like forklifts.

Dock boards vs dock plates

The main difference between dock boards and dock plates shows in how they’re built and used. Dock boards have curbs on the edges that make them safer and more stable, so they can handle more weight. Built mostly from steel, dock boards support 10,000 to 30,000 pounds, making them great for forklift work. Dock plates don’t have curbs and are usually made of aluminum. They handle less weight, between 5,000 to 20,000 pounds.

When to use a dock leveler vs a dock plate

The right equipment for your loading dock depends on operational factors that affect efficiency and safety. Your choice between dock levelers and dock plates can affect your facility’s productivity.

High-volume loading docks

Hydraulic dock levelers are without doubt the best choice for busy warehouses with constant truck traffic. These strong systems work well in the ever-changing pace of high-volume loading docks and many busy facilities worldwide prefer them. Hydraulic dock levelers can handle loads up to 100,000 pounds and easily manage heavy equipment like forklifts that move between the warehouse and delivery trucks. The push-button operation helps reduce operator fatigue, which matters a lot in fast environments where efficiency is key.

Light-duty and manual operations

Dock plates work best with lighter loads and non-powered equipment. We designed these portable aluminum plates for non-motorized pallet jacks, hand carts, and dollies. They fit perfectly in lower volume loading environments. Dock plates weigh less than dock boards, so workers can place them manually. These plates work great for delivery vehicles and operations that don’t need powered equipment. Note that dock plates should never be used with gas or electric powered equipment.

Facilities with varying truck heights

Hydraulic dock levelers give facilities that receive multiple truck types the versatility they need. A hydraulic leveler serves as the best option for docks with varying heights because it adjusts to different truck heights. Dock plates work best with small height differences of less than 5 inches. However, dock levelers can handle bigger variations, usually working within a range of 12 inches above and below dock height. This flexibility makes them a great choice for warehouses that service different vehicle fleets.

Temperature-controlled environments

Vertical storing dock levelers bring benefits to temperature-sensitive environments. These levelers store vertically inside cold storage facilities. The doors can close tightly against the floor with this design, which eliminates gaps and stops energy loss. Vertical storing levelers not only save energy but also let workers clean thoroughly beneath the equipment. This feature matters greatly in food, pharmaceutical, and other perishable product facilities that need strict sanitation standards.

Cost, installation, and maintenance comparison

Your loading dock equipment’s cost goes way beyond the original purchase price. Equipment installation complexity, maintenance needs, and energy usage all play a role in what you’ll end up paying over time.

Installation requirements

Each equipment type’s installation process is different. Dock plates are ready to use right away since you can move them around. Dock levelers need more work. Pit-style models take weeks to build and include permits, demolition, and concrete work. The exterior-mount versions are easier, you can bolt them on in just 1-2 days for each dock door. Without a pit already in place, you’ll need 1-2 weeks to cut the floor, let concrete cure, and finish setup.

Maintenance needs and lifespan

Hydraulic dock levelers usually work for 10-15 years. Mechanical models last 5-7 years before you need new ones. Each type needs different care. Hydraulic systems need their electrical connections and fluid levels checked every three months. Mechanical units need more attention, especially their spring mechanisms that are always under pressure. You should get professional maintenance twice a year for normal use, or monthly if your facility runs multiple shifts.

Every Business Has Different Needs

Your facility’s specific operational requirements will determine the choice between dock levelers and dock plates. Dock levelers are the better option for high-volume warehouses that handle heavy loads with powered equipment. Hydraulic models might cost more upfront but deliver the best value through their longer lifespan, lower maintenance needs, and better energy efficiency.

Dock plates work great as budget-friendly options for light-duty operations where height differences are small. These portable units with their simple design fit perfectly in facilities that use hand trucks and pallet jacks.

Take time to evaluate your daily operations before deciding. Look at your loading frequency, equipment types, truck height variations, and budget limits. Focus on the total cost of ownership rather than just the upfront investment. A hydraulic dock leveler might seem expensive now but can save money over time through reduced maintenance and energy costs. A basic dock plate could fall short as your operations grow.

Safety must be your top priority whatever equipment you choose. The right equipment prevents accidents, reduces worker strain, and helps operations run smoothly. Dock levelers come with detailed safety features, but dock plates need proper handling and weight capacity monitoring to keep the workplace safe.

The right loading dock equipment improves productivity and streamlines operations while protecting your workers and products during transfers between vehicles and your facility.